General causes of safety issues in HSE industries

In HSE industry, safety is the most crucial criteria which all employer of labour under this industry must be able to provide for everyone within their reach. It could either be their staff, clients or people around their company. The most needed thing is safety for all.

There are certain general situation which are safety disoriented, though this situation may sometime look casual and simple, personnel on ground must be sensitive enough to handle them Professionally to ensure safety of the community.

Below are five general causes of safety issues in workplace

1. Rushing sensitization process.

Due to the fact that companies may have targeted goal for a day, week or month. Company and individual on duty are downtime forced to speed up the process of training staffs on work process, a lot of time the speed up in these processes may cause the Employees more side effect since there was not enough time to assimilate and process things which were taught for practice and this often lead to lot of safety Hazards.

Companies must learn to take time in training and following up with Employee as this does not only help their level of understanding but also help to reduce general safety issues which can be avoided.

2. Procrastination of Maintenance and inspection

Inspection should be done regularly to avoid issues which may lead to serious damage to the company or the Employees e.g Machine which is faulty should be checked immediately and fixed. The company should have a firm standing on solving problem as the need arise.

The need for immediate inspection is very important, as this help to put situation in check and ensure they meet up with regulatory standard .

Productivity and growth depend on how fast and active the inspection and maintenance of the company is, in order not to have work under flow both inspection and maintenance must be immediate without delay.

3. Negligence of near destruction moment.

While many safety incidents result in workplace injuries, some scenarios don’t result in injuries. It’s possible these situations may be written off as there is no specific injury to report.

But companies should take these close calls, or near-misses, seriously. Once reported, these incidents should be investigated and tracked, as should the corrective actions that they inspire.

4. The use of manpower instead of machine.

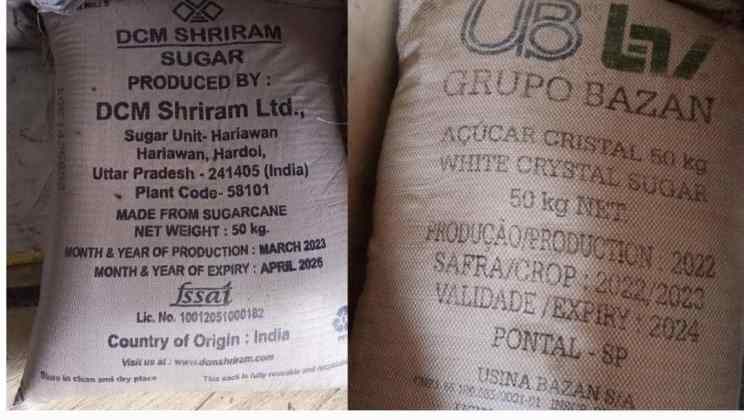

Some certain error can easily be corrected if the company would go for usage of machine instead of manpower, but a lot of time, companies end up considering cost and availability and these at time may lead to safety defect. E.g a cutting edge machine would do an effective work in faster time than an employee using sharp objects to cut and shape the material, apart from the time consumption of using manpower, there are also likely going to be a large volume of product defect which most time will negate the safety of the product .

5. Failure to invest in health and wellness.

There are lot of issues which could be avoided if companies invest in the wellness of her Employees e.g availability for first aid box, also the first aid box should contain all essentials.

Material that can make work less tedious should also be made available as their will not only boost the production rate but the health and wellness of the employees.

All these point listed above can be easily worked on If the company take it upon themselves to fix general situation that causes safety issues.

HSENations